Water

LEAD MANAGEMENT

Conquer the battle

You don’t need to visit every lateral. Really. Use Machine Learning to convert unknowns to knowns. Spend your time replacing lead or galavanized instead of trying to find it.

LCRR INVENTORY

Hello predictive modeling

Some states are accepting Predictive Modeling as a way of completing your LCRR inventory. Yours could be one of them.

Create a strong case while keeping your costs low.

Locate. Act. Prevent.

Stop relying on the installation year and use Machine Learning to find out where lead pipes are located. Make better planning decisions and minimize health risks in your community. VODA.ai LeadFinder works for public and private laterals.

FOR SAMPLING

AND REPLACEMENTS

justify the absence of lead

Plan quickly and effectively. Figure out which pipes you need to get samples from, and use VODA.ai LeadZero to create a case for DEP.

LEAD MANAGEMENT

LEAD MANAGEMENT

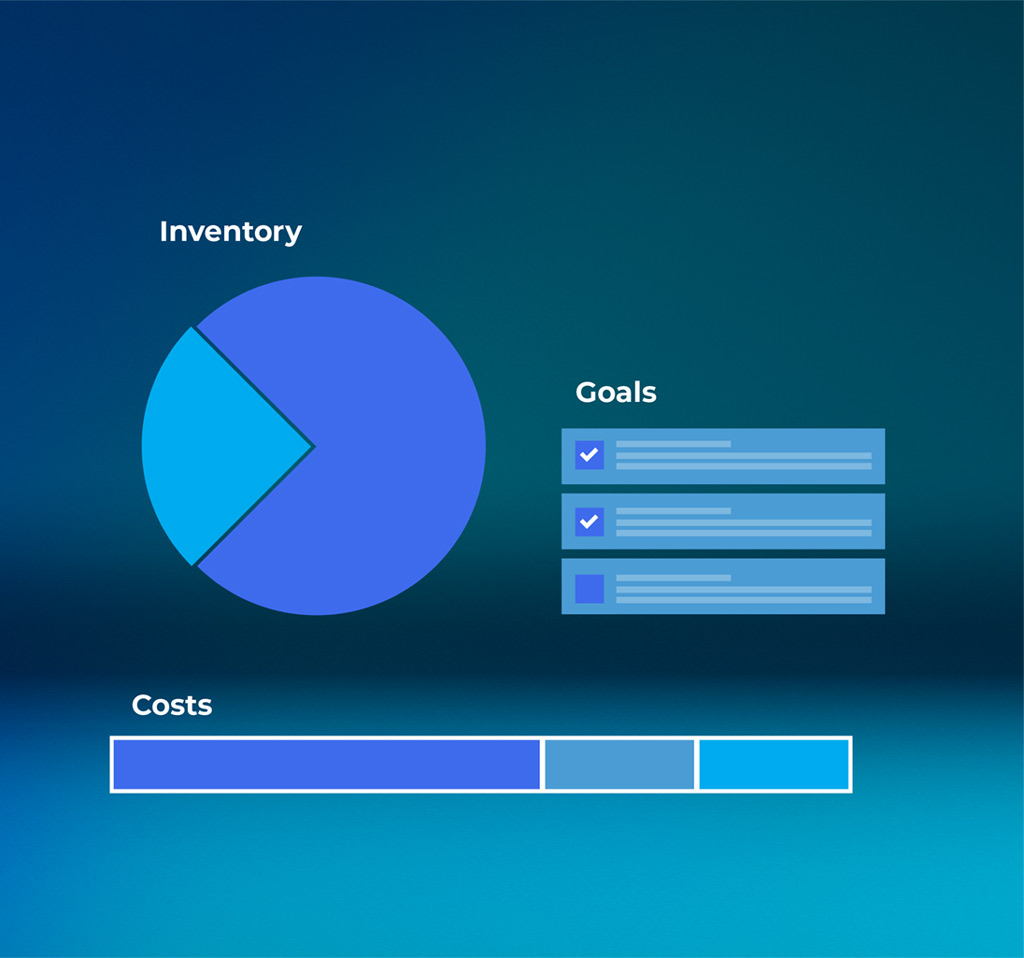

Inventory, costs, goals

all in one screen.

Monitor lead service inventory and replacement goals and have all the information you need readily available. Detect lead pipes early and prevent health risks. Submit your inventory on time and on budget.

Monitor lead service inventory and replacement goals and have all the information you need readily available. Detect lead pipes early and prevent health risks. Submit your inventory on time and on budget.

“DaVinci has shown us and our customers that it can do more than failure predictions. It can also identify lead service lines, helping water systems cost effectively achieve compliance with the Lead and Copper Rule Revisions and better plan for replacements.”

Lead Management isn’t complicated anymore.